PowerFlex® series induction heating power supplies

with Multi Frequency Technology

Induction Systems, Inc. has re-written the book on power supplies. Gone are the days of frequency controlled, un-tunable, noisy SCR units.

We have stepped out of the big companies' rule-books and have created our own set of standards. Our power supplies have been designed specifically for commercial heat treating. An industry that is saturated with power supplies that were originallly designed for forging and melting. Units that often times cause challenges due to their lack of tune-ability. As the result of our proprietary circuit design, all of our units start in any tuning condition.

PowerFlex power supplies were designed to solve the many issues facing today's heat-treaters. With its multi-frequency and ease-of-use technology, its abililty to tune a wide range of coil sizes, and frequency-flexibility to meet the required case depths, PowerFlex has fast become the "go to" power source.

Every aspect of our power supplies, from board to components, are designed and manufactured in our plant in Waukesha, WI. Our products and systems are crafted and built with the utmost precision, pride and dedication.

125 kW 10 kHz to 100 kHz

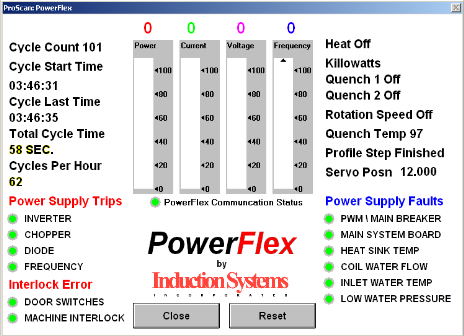

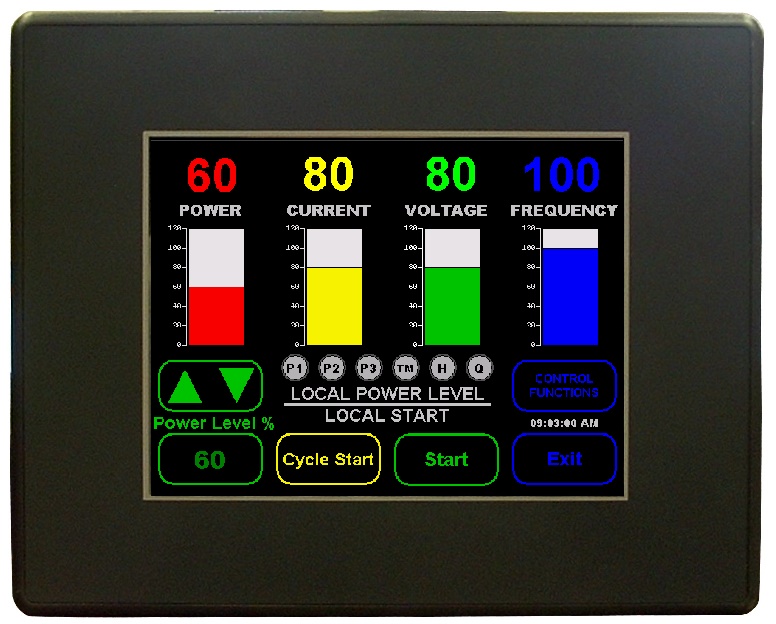

Stand-alone meter & fault screen